After working in the synthetic fiber industry for many years, one thing I have learned is that polyester staple fiber (PSF) often sounds far more complicated than it actually is. Many newcomers—whether they are buyers, textile students, or professionals entering the fiber supply chain—struggle to understand how PSF is produced and why each step matters.

In reality, the manufacturing process follows a clear and logical sequence. Once you understand the purpose of each stage, the entire process becomes much easier to grasp. Below, I will walk you through how polyester staple fiber is made, step by step, based on practical industry experience rather than textbook theory.

DMT

Every polyester staple fiber begins with raw materials, and this choice directly affects fiber quality, cost, and sustainability.

Traditionally, PSF is made from petrochemical-based raw materials, mainly purified terephthalic acid (PTA) or dimethyl terephthalate (DMT), combined with monoethylene glycol (MEG). These materials react to form polyethylene terephthalate (PET), the same polymer used in polyester filament yarn and PET bottles.

In recent years, recycled polyester staple fiber has become increasingly common. In this case, the raw material comes from post-consumer PET bottles or industrial polyester waste. These materials are cleaned, crushed into flakes, and reprocessed into polymer chips. From a manufacturing perspective, recycled and virgin PSF follow very similar downstream processes, but raw material purity control becomes more critical when recycling is involved.

From my experience, beginners often underestimate this stage. In reality, stable raw material quality is the foundation of consistent fiber performance, influencing tensile strength, dyeability, and processing efficiency in spinning mills.

Once the raw materials are prepared, the next step is polymerization, where small molecules are chemically bonded into long polyester chains.

During this process, PTA (or DMT) reacts with MEG under controlled temperature and pressure conditions. Through esterification and polycondensation reactions, polyester polymer melt is formed. The molecular weight and viscosity of this melt are closely monitored, as they determine how well the material can be spun into fibers.

From an operational standpoint, this stage is all about control. Too low a viscosity leads to weak fibers; too high, and spinning becomes unstable. In modern PSF plants, online sensors and automated systems are used to maintain polymer consistency.

For beginners, the key takeaway is simple: polymerization determines the “DNA” of polyester staple fiber. If this step is poorly controlled, no amount of downstream adjustment can fully compensate for it.

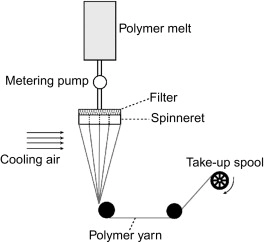

Once the polyester melt reaches the correct specifications, it moves into melt spinning, the heart of polyester staple fiber manufacturing.

The molten polymer is extruded through a spinneret, a metal plate with hundreds or thousands of tiny holes. As the melt passes through these holes, it forms continuous polyester filaments. These filaments are immediately cooled—usually by controlled air flow—so they solidify into stable fiber strands.

From years on the production floor, I can say that spinneret design and cleanliness are often overlooked by newcomers. In practice, uniform hole size and smooth melt flow are critical to achieving even fiber thickness and minimizing defects such as broken filaments or uneven denier.

At this stage, the fibers are still smooth, straight, and relatively weak. They look nothing like the final polyester staple fiber used in textiles, which is why further processing is essential.

After spinning, the filaments undergo drawing, a mechanical stretching process that aligns the polymer molecules along the fiber axis. This molecular orientation dramatically improves tensile strength, dimensional stability, and durability.

Once drawing is complete, the fibers are crimped. Crimping introduces controlled waves or bends into the fibers, giving polyester staple fiber its characteristic bulk and elasticity. This step is especially important for textile applications, as crimped fibers spin better and produce fabrics with improved softness and resilience.

From a practical perspective, this is where fiber personality is created. Adjusting drawing ratios and crimp levels allows manufacturers to produce PSF suitable for different uses—whether for apparel, home textiles, nonwovens, or industrial applications.

Simply put, drawing builds strength, while crimping builds comfort and usability.

The final stage is where continuous filaments are transformed into staple fibers.

The crimped tow is cut into specific lengths—commonly 32 mm, 38 mm, or 51 mm—depending on the intended spinning system and end use. After cutting, the fibers undergo finishing treatments, such as applying spin finishes that improve antistatic performance and processing smoothness.

Before packaging, strict quality control inspections are carried out. Parameters such as fiber length, denier, crimp stability, moisture content, and tensile strength are tested to ensure consistency.

Based on industry experience, this stage often determines customer satisfaction. Even small variations can cause problems in spinning or fabric formation. That is why reputable polyester staple fiber manufacturers invest heavily in final inspection and process standardization.

Once approved, the PSF is baled and ready for shipment to spinning mills and nonwoven producers worldwide.