From apparel and home textiles to nonwoven fabrics and automotive interiors, PSF plays a critical role in modern manufacturing. For buyers, understanding what polyester staple fiber is—and why it performs so reliably across industries—is essential for making informed sourcing and material decisions.

Polyester staple fiber refers to short-length polyester fibers, typically cut to specific lengths (such as 32 mm, 51 mm, or 64 mm), designed to be spun or processed in a manner similar to natural fibers like cotton or wool.

Unlike polyester filament fiber, which is continuous and smooth, polyester staple fiber is discontinuous. This structure allows PSF to be blended easily with other fibers, improving fabric texture, cost efficiency, and functional performance. Chemically, PSF is primarily made from polyethylene terephthalate (PET), the same polymer used in many plastic bottles and films.

In industrial terms, polyester staple fiber is valued for its consistency, scalability, and adaptability, making it a cornerstone material in both traditional textiles and advanced nonwoven applications.

The manufacturing process of polyester staple fiber is a highly controlled industrial operation designed to ensure uniform quality and performance.

It typically begins with either:

1. Virgin PET chips, derived from petrochemical raw materials, or

2. Recycled PET flakes, sourced from post-consumer plastic bottles.

The process involves melting the PET material, extruding it through spinnerets to form continuous filaments, and then cooling and stretching the filaments to enhance molecular orientation and strength. These filaments are subsequently crimped, heat-set, and cut into staple lengths, resulting in finished polyester staple fiber.

Key production variables—such as draw ratio, crimp frequency, fiber denier, and cut length—directly affect the final fiber properties. For customers, these parameters determine whether a PSF is suitable for spinning, thermal bonding, needle punching, or other downstream processes.

One reason polyester staple fiber is so widely adopted lies in its balanced and predictable performance profile.

PSF offers:

• High tensile strength and abrasion resistance, ensuring durability in repeated use

• Excellent dimensional stability, even under heat and mechanical stress

• Low moisture absorption, reducing mold growth and drying time

• Chemical resistance, particularly against acids and common solvents

In addition, manufacturers can engineer PSF with specific features, such as:

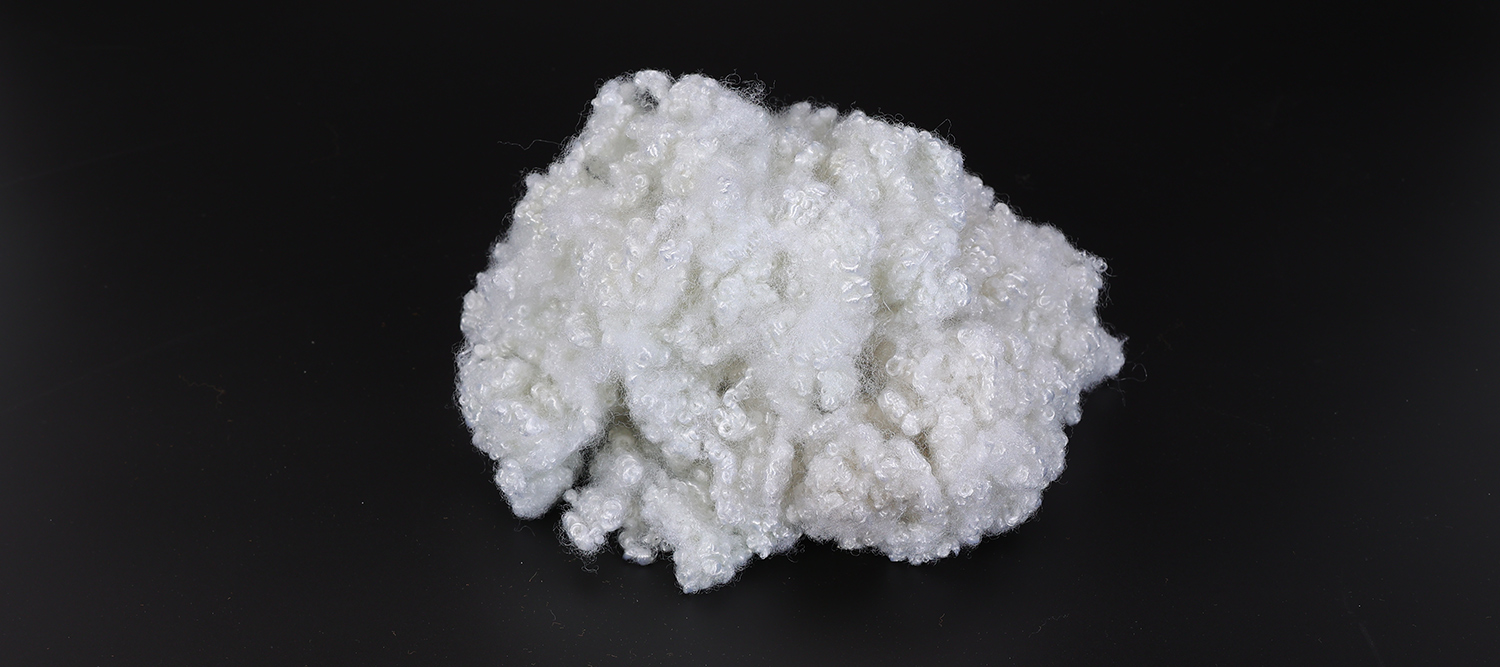

• Hollow structures for insulation and lightweight filling

• Low-melting sheaths for thermal bonding

• Siliconized finishes for enhanced softness and resilience

These characteristics make polyester staple fiber especially attractive for industrial buyers seeking long service life, stable supply, and controlled quality.

Polyester staple fiber is used across a broad range of industries, often as a performance-driven alternative to natural fibers.

In textiles, PSF is commonly found in yarns, woven fabrics, knitted fabrics, and blended materials that combine strength with cost efficiency.

In nonwoven applications, polyester staple fiber is essential for products such as:

• Geotextiles and filtration media

• Automotive interiors and insulation felts

• Medical and hygiene products

• Construction and roofing materials

In home furnishing, PSF is widely used for pillow filling, quilts, upholstery padding, and mattresses due to its resilience, loft retention, and ease of maintenance.

This versatility allows buyers to standardize materials across product lines while still meeting diverse technical requirements.

From a B2B perspective, polyester staple fiber is not just popular—it is strategically reliable.

PSF offers a rare combination of:

• Cost competitiveness compared with natural fibers

• Stable global supply chains

• Customizable specifications for different applications

• Compatibility with recycled content, supporting sustainability goals

As sustainability becomes increasingly important, recycled polyester staple fiber (rPSF) has gained significant traction. It allows manufacturers to reduce environmental impact while maintaining nearly identical performance to virgin fiber.

For manufacturers, converters, and brand owners alike, polyester staple fiber remains a material of choice that balances performance, price, and scalability, ensuring its continued relevance in global markets.